SEM engineering

Customized machinery for the ceramic industry since 1983

From kiln infeed to final line. Specialized in Polishing, Cutting and Squaring ceramic lines

FROM SMALL SIZES TO BIG SLABS

SEM has been developing complete and customized processes of polishing, cutting and squaring since 1983.

CUSTOMIZED SOLUTIONS FOR THE INDUSTRIES

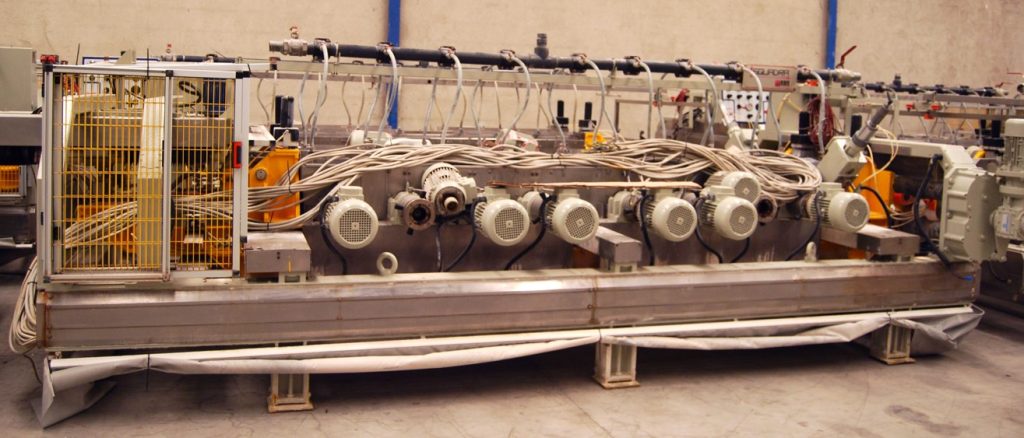

Complete Polishing, Cutting and Squaring Lines

We assemble complete finishing polishing, cutting and squaring lines for the ceramic industry. The mechanical processing of technical porcelain is divided into three stages:

- The first involves rough grinding using a roller calibrating unit to remove surface roughness.

- The second involves grinding, which uses tangential heads and medium and fine grinding tools to remove any roughness or grooves left by the calibrator unit and makes the surface extremely smooth in preparation for lapping.

- The third stage is lapping, which uses tangential heads fitted with super fine polishing tools.

Surface polishing process (on glazed surfaces and technical porcelain) consists of grinding the surface of the tile, which significantly improves the aesthetic appearance of the finished product.

Customized machinery and technical support

We adapt the machines to the customer’s requirements. We have machinery for all sizes and formats, from small to big slabs. In addition, we adapt the machine’s dimensions to the work space of each client, always looking for the most efficient solution. We also provide technical support

OCASION MACHINERY

We provide second hand machinery. Squaring, polishing and cutting machines are available and ready to ship around the world. SEM has second hand machines available. Ask for further information: comunicacion@sem-engineering.com

CUSTOMIZED MACHINERY

Picking XXL and SMALL sizes

SEM develops a manual handler for picking and palletizing XXL formats and big slabs. Using vacuum technology the piece is allowed to spin up to 180 degrees (watch the video).

Also, We offer semi-automatic and automatic feeders for all loading types. You can pick from small sizes to big slabs. We adapt the machines to your requests.

Tile stacker / kiln emergency

Tile stacker/kiln emergency stacks the product when it get out the kiln in order to transport it to another line or to store the material because the kiln has been stopped because there was any problem.

This system prevents sick leaves due to accidents because it does a manual extraction of the material. Also, it adapts to all formats, from 60 x 60 cm.

The tile stacker/kiln emergency loads the ceramic on pallets in an orderly manner, preventing the pieces from being damaged, broken or scratched. Which translates into a reduction of the lower class of the material. In fact, it allows reintroducing the extracted tiles into the line once the emergency is solved.

This novelty by SEM also allows palletizing the product directly from the kilt in case part of the production is outsourced, to a polishing, cutting and grinding plant such as Polished the Flat (PLP), thus eliminating packing costs.

Load and Unload with vacuum grip

Compenser. Belt conveyors, curve belts, roller conveyors, cleaning brushes, etc.

Conveying Lines

Industrial water depuration

Soundproof booth

Kiln Infeed and Way Out Machine

Curve Belts

Processes Automation